2020.07.29 Hyundai Motor Company

'Eco-friendliness' is the first thing people consider when talking about future mobilities; global warming tells us it really is time to reduce emission. Hence the growing EV and FCEV markets. However, just because the vehicles are green does not necessarily mean they get to become the next-generation icon. Not so fast. They also need to be safe and, last but not least, affordable. So, how exactly safe and cost-efficient are FCEVs?

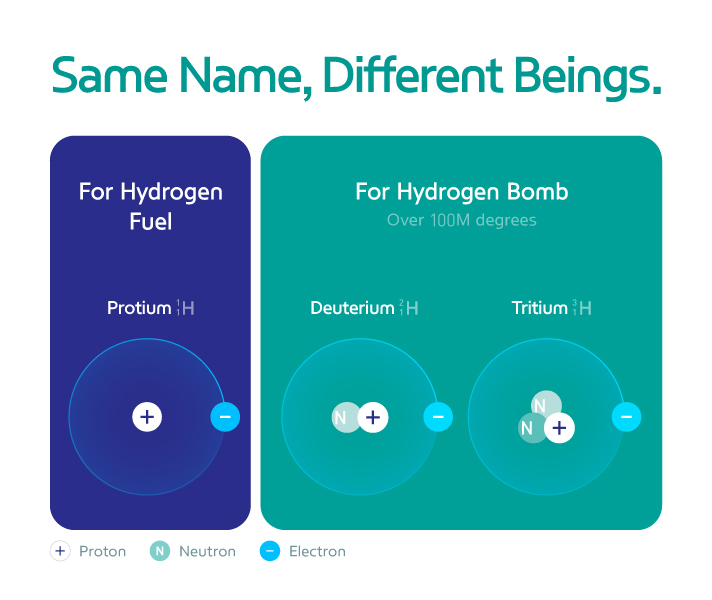

FCEVs are mostly stereotyped as 'explosive', frightened by the word-association with the hydrogen-bomb. Hydrogen utilized by FCEVs is in the form of hydrogen molecules; Protium, to be specific. Protium, which is the most common hydrogen isotope, constitutes 99.985% of all hydrogen atoms, and has one Proton and one Electron. This type of hydrogen gas is pressurized at about 700bar of pressure and stored in a cryogenic tank. In the case of the hydrogen bomb, however, materials are not pressurized hydrogen gas, but deuterium and tritium. Both deuterium and tritium are extremely in their natural states and require tremendous energy to subsist. Even if deuterium and tritium were present, getting the explosive power of a hydrogen bomb will require extreme heat and pressure. That is, over a hundred million degrees at thousands of bars of pressure. Such heat and pressure necessary to detonate a hydrogen bomb actually require the detonation of a smaller nuclear bomb to kindle a fusion reaction.

Gasoline, liquefied petroleum gas, and LNG are 1.44, 1.22, and 1.03 times more dangerous than hydrogen, respectively, according to Korea Gas Safety Corp. and The American Institute of Chemical Engineers (AIChE). Besides, hydrogen is a gas much lighter than the atmosphere, so it immediately vaporizes into the air if there is a leak. Even in the case of a vehicle fire, the chances of leaked hydrogen combusting is virtually nonexistent since the ignition temperature of hydrogen is about 500℃.

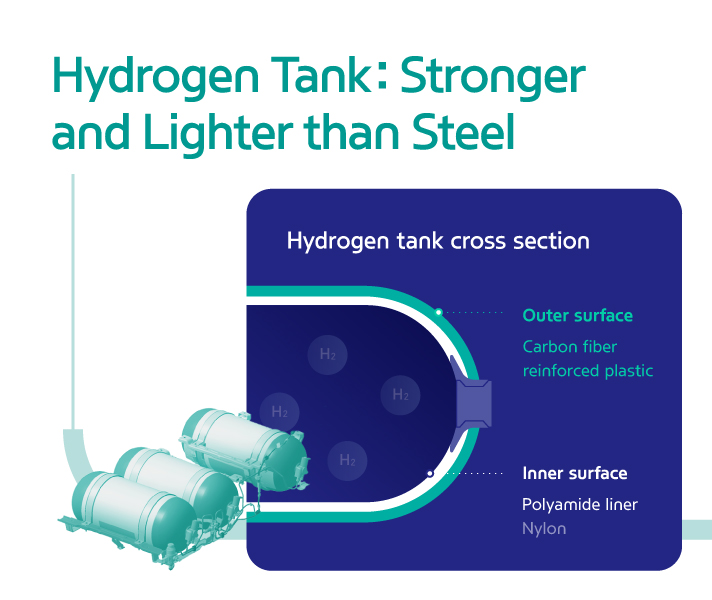

The hydrogen tanks are almost ever-lasting. Speaking of ones in the Hyundai Nexo, the inner surface of the hydrogen tanks are made of a thin polyamide liner (nylon) that minimizes hydrogen permeation. The outer surface is covered in reinforced plastic (carbon fiber + epoxy) capable of maintaining a pressure of 700 bar. Carbon fiber reinforced plastics have many benefits over steel by weight. Two of such benefits are 6-times greater strength and 4-times greater stiffness. In other words, reinforced plastics are lighter while being more dependable.

In a rear-impact test performed under conditions identical to standard internal combustion engines, the hydrogen tanks had ejected all hydrogen, and not even trace amounts were detected. Also, the hydrogen tanks have withstood drop-tests without any damage to their functions. Even if there is a vehicle fire, redundant fire-resistant materials and safety mechanisms prevent escalation while rapidly expelling hydrogen contents, thereby preventing any possibility of an explosion. A bullet shot into a hydrogen tank resulted only in hydrogen gas being emitted into the atmosphere through the puncture, with no explosion. The tanks, of course, survived not only contaminants but also extreme climates.

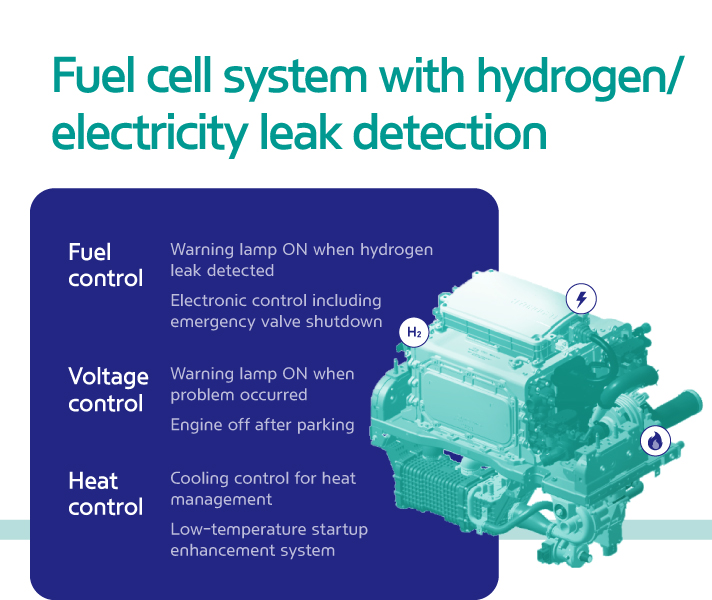

The fuel cell system reacts hydrogen and air to produce electrical energy. And because of its high voltage current, it is essential to maintain insulation resistance so that the current does not flow out of the circuit, and even if there is a leakage, the electrical continuity between parts must be secured. Since hydrogen gets into the fuel cell stack, it is also important to watch out for hydrogen leaks. Apparently, it is necessary to keep both electrical and hydrogen safety at the same time.

For this reason, the fuel cell system mounted on FCEVs should prove its safety and durability through various tests, such as insulation, leak rate, durability, vibration and shock resistance, waterproof and dustproof, corrosion resistance, and high/low-temperature tests. The fuel cell system of the Hyundai Nexo has also survived such tests, and it comes with a 10-year 160,000km durability guarantee.

In case of emergency, there are multiple real-time sensors that detect any leakage on the fuel tank, feed system, and the fuel cell stacks. If a hydrogen leak is detected, either during standard operation or in an external impact that damages the feed system, the driver’s dashboard display puts up a warning. The safety system may even choke the hydrogen fuel tank valve, preventing mass ejection of hydrogen from the tank, which may lead to other hazards, then the system turns off the engine after it guides the driver to park the vehicle immediately. The heat control system activates cooling system to manage heat from chemical reaction of oxygen and hydrogen inside the fuel cell stack.

The price of hydrogen-powered cars is more expensive than those of internal combustion engines or electric vehicles in similar sizes. But you will see how affordable FCEVs can be when you buy one. This is because countries including South Korea are offering government subsidies. Speaking of Korea, the central government would give you 22.5 million KRW, not to mention local governments offering 10 to 20 million KRW (may vary from regions, as of 2020). These offers make the actual purchase price look quite similar to that of a regular SUV. In addition, FCEV owners can get various tax exemptions, including the registration fee.

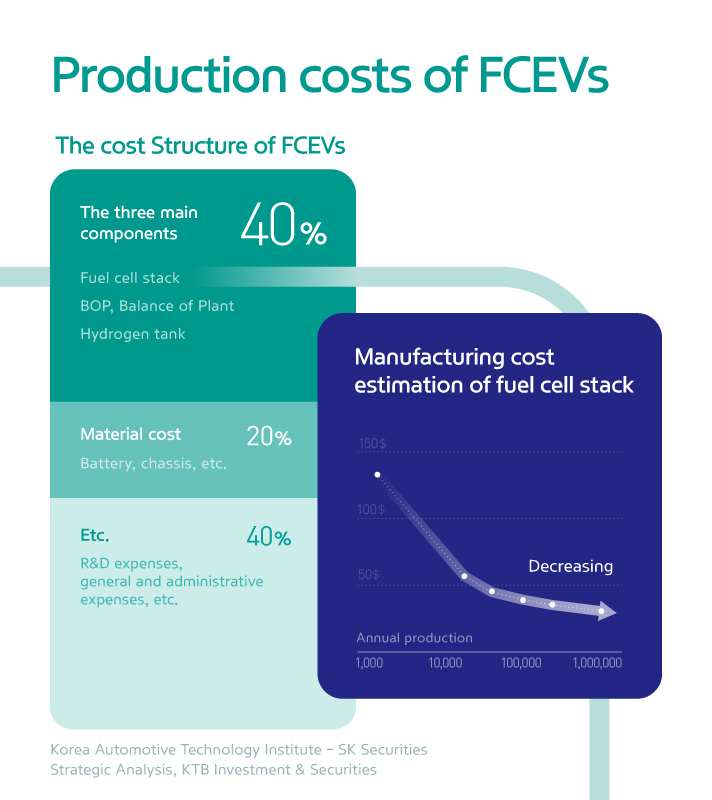

FCEVs are expensive because of the core components such as fuel cell stacks. The size of the FCEV market is still in its early stages, and their lack of supply makes the production costs high. However, when demand exceeds supply, the production cost including fuel-cell stacks and hydrogen tanks will surely decrease, making FCEVs much more affordable in the future. And when the day comes, FCEVs will no longer need any government subsidies.

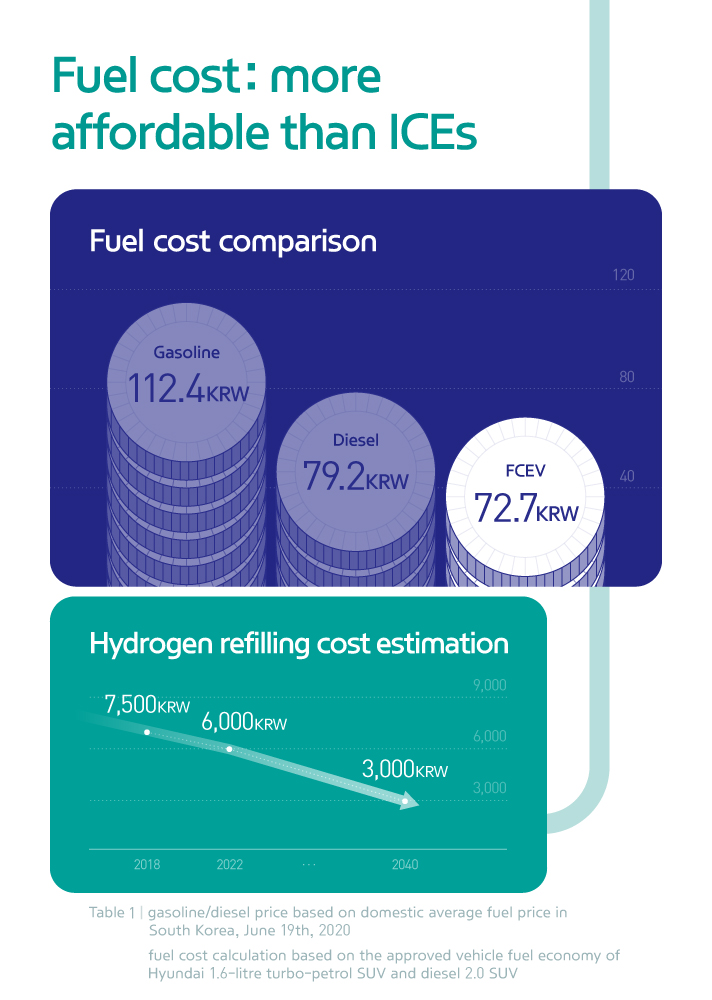

When it comes to the cost-efficiency of a car, fuel costs are as important as its initial price tag. Although there is a fluctuation depending on international oil prices, the fuel cost per kilometer of current FCEVs is already lower than those of internal combustion engines that use gasoline or diesel, and their competitiveness will continue to grow as the hydrogen market expands and the infrastructures for production increases. In a roadmap to boost the hydrogen economy, the Korean government announced it will increase the supply of hydrogen fuel by 2040, lowering the price to 3,000 KRW per kilogram, which would be less than half of the current price.

The cost of replacing consumables is less than that of ICEs. Except for the motor part that generates electricity using hydrogen fuel, FCEVs and ICEs have a lot in common in terms of operation. In other words, there is no need to replace engine-related consumables. It is not necessary to replace, say, engine oil, transmission oil, various belts, fuel filters, or ignition plugs.

FCEVs are not only eco-friendly but also safe and cost-efficient. The Hyundai Nexo has earned the top safety pick among the latest models in multiple countries. It is also expected to become much more competitive for its price tag and maintenance/operating cost as the EV market continues to grow.